Turn-Key CNC Routing Shop – PRO408 ATC, Forklift, All Digital Assets

Asset Sale Description

This offering includes the complete assets, brand, digital infrastructure, and documented processes of Rocky Mountain CNC Works, a fully equipped CNC manufacturing facility in Pueblo, Colorado. The operation has proven capability across wood, plastics, composites, and foam, and is configured for immediate production. The business is set up for immediate production, with all major equipment, tooling, software, and systems in place. The sale includes all equipment, software, IP, customer lists, and the Rocky Mountain CNC Works name. No future revenue is represented or implied.

Website: https://rm-cncworks.com

Materials Processed

• Plastics and Industrial Polymers. ABS, Acrylic, Delrin/Acetal, HDPE, Nylon, PET/PETG, Polycarbonate, PVC, UHMW.

• Wood and Engineered Panels. Plywood, MDF, HDF, HPL/TFL panels, Particleboard, solid wood and timbers.

• Closed-Cell Foam. XLPE/XPE, HDU, expanded PVC.

• Composites. ACM/MCM, Phenolic resin, Thermoplastic composites, foam-core laminates, solid surfaces.

Facility & Infrastructure

• 5,000 sq ft industrial space designed for CNC production.

• 3-phase power, dust collection, compressed air distribution, and more than $25k in electrical upgrades.

• Efficient layout for sheet-goods machining, fixturing, assembly, and material handling.

• Facility lease can be transferred to the buyer with landlord approval, or assets may be relocated.

Major Equipment

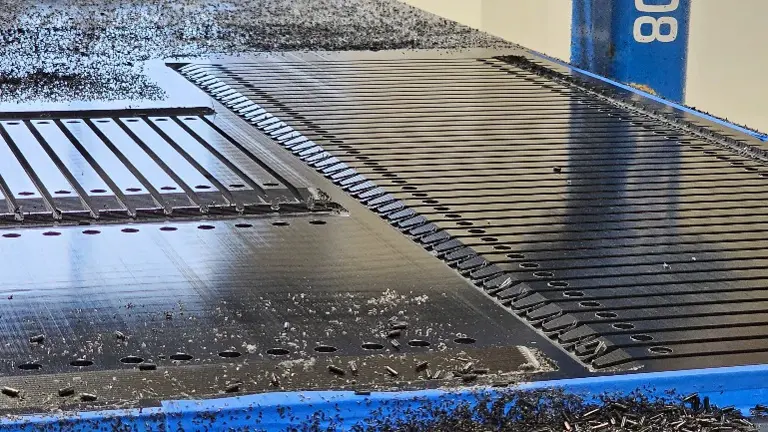

• ShopSabre PRO408 ATC CNC Router with 10hp HSD spindle, 10-position automatic tool changer, and Becker VTLF 2.250 vacuum pump.

• Toyota 5,000 lb forklift (low hours).

• Big Joe S-22-116 walkie/stacker with new batteries.

• Powermatic PJ882-HH helical jointer, Powermatic planer, 5hp table saw, router table, Festool sanders, and extensive clamps and tooling.

All business- and manufacturing-related assets, including:

• The business name Rocky Mountain CNC Works and all associated branding

• Website and domain name (rm-cncworks.com) and all associated digital assets

• Customer and supplier lists

• All manufacturing-related digital assets, including CAD models, CAM files, nesting setups, toolpath strategies, fixture designs, and process documentation, MRPEasy database

• Option to assume current lease under favorable terms

Recent & Ongoing Work

The shop has produced parts for furniture companies, outdoor products, OEM manufacturers, and retailers. Examples include Baltic Birch retail display parts, MDF/HDF furniture components, industrial polycarbonate parts, UHMW components, and various prototyping and custom routing jobs. Several product lines and customer relationships can be transitioned to the buyer if desired.

Turn-Key Value

The sale includes all major equipment, fixturing, tooling, digital workflow assets, and documented processes needed to begin production immediately. The facility is already built out for high-volume CNC routing, saving a buyer significant startup time and infrastructure cost.

Liens & Payoffs

Any remaining equipment loans or leases on included assets will be paid off at closing using buyer funds. Buyer receives clear title to all assets transferred.

Support & Training

The seller is available to provide hands-on training in CNC operations, production workflows, fixturing, tool selection, QC procedures, and job setup. Extended support or consulting can be arranged if needed. Customer and supplier introductions will be provided where appropriate.

Reason for Sale

Owner is pursuing other opportunities and seeks a smooth transition to a qualified operator who can take advantage of the existing equipment and facility.

Serious inquiries only. NDA required prior to release of full equipment list and financials.

Website: https://rm-cncworks.com

Materials Processed

• Plastics and Industrial Polymers. ABS, Acrylic, Delrin/Acetal, HDPE, Nylon, PET/PETG, Polycarbonate, PVC, UHMW.

• Wood and Engineered Panels. Plywood, MDF, HDF, HPL/TFL panels, Particleboard, solid wood and timbers.

• Closed-Cell Foam. XLPE/XPE, HDU, expanded PVC.

• Composites. ACM/MCM, Phenolic resin, Thermoplastic composites, foam-core laminates, solid surfaces.

Facility & Infrastructure

• 5,000 sq ft industrial space designed for CNC production.

• 3-phase power, dust collection, compressed air distribution, and more than $25k in electrical upgrades.

• Efficient layout for sheet-goods machining, fixturing, assembly, and material handling.

• Facility lease can be transferred to the buyer with landlord approval, or assets may be relocated.

Major Equipment

• ShopSabre PRO408 ATC CNC Router with 10hp HSD spindle, 10-position automatic tool changer, and Becker VTLF 2.250 vacuum pump.

• Toyota 5,000 lb forklift (low hours).

• Big Joe S-22-116 walkie/stacker with new batteries.

• Powermatic PJ882-HH helical jointer, Powermatic planer, 5hp table saw, router table, Festool sanders, and extensive clamps and tooling.

All business- and manufacturing-related assets, including:

• The business name Rocky Mountain CNC Works and all associated branding

• Website and domain name (rm-cncworks.com) and all associated digital assets

• Customer and supplier lists

• All manufacturing-related digital assets, including CAD models, CAM files, nesting setups, toolpath strategies, fixture designs, and process documentation, MRPEasy database

• Option to assume current lease under favorable terms

Recent & Ongoing Work

The shop has produced parts for furniture companies, outdoor products, OEM manufacturers, and retailers. Examples include Baltic Birch retail display parts, MDF/HDF furniture components, industrial polycarbonate parts, UHMW components, and various prototyping and custom routing jobs. Several product lines and customer relationships can be transitioned to the buyer if desired.

Turn-Key Value

The sale includes all major equipment, fixturing, tooling, digital workflow assets, and documented processes needed to begin production immediately. The facility is already built out for high-volume CNC routing, saving a buyer significant startup time and infrastructure cost.

Liens & Payoffs

Any remaining equipment loans or leases on included assets will be paid off at closing using buyer funds. Buyer receives clear title to all assets transferred.

Support & Training

The seller is available to provide hands-on training in CNC operations, production workflows, fixturing, tool selection, QC procedures, and job setup. Extended support or consulting can be arranged if needed. Customer and supplier introductions will be provided where appropriate.

Reason for Sale

Owner is pursuing other opportunities and seeks a smooth transition to a qualified operator who can take advantage of the existing equipment and facility.

Serious inquiries only. NDA required prior to release of full equipment list and financials.

Detailed Information

- Years in Operation

- 4

- Facilities & Assets

- 5,000 sq ft CNC production facility with 3-phase power, full dust collection, compressed air, and major electrical upgrades for CNC production. Assets include a ShopSabre PRO408 ATC router with 10hp spindle, Becker vacuum system, Toyota forklift, Big Joe stacker, dust collectors, Powermatic jointer and planer, 5hp table saw, Festool sanders, custom CNC fixturing, tool storage, and computers. Manufacturing and business-related information included. Ready for immediate production.

About the Sale

- Transition Support

- Training available on CNC operation, CAM workflows, fixturing, tooling, QC, and production processes. I can assist with customer & supplier introductions and workflow documentation. Extended transition support or consulting is available if needed.

- Seller Motivation

- Owner is pursuing other opportunities

Listing Info

- ID

- 2439399

- Listing Views

- 205

Listing ID: 2439399 The information on this listing has been provided by either the seller or a business broker representing the seller. BizQuest has no interest or stake in the sale of this business and has not verified any of the information and assumes no responsibility for its accuracy, veracity, or completeness. See our full Terms of Use. Learn how to avoid scams.